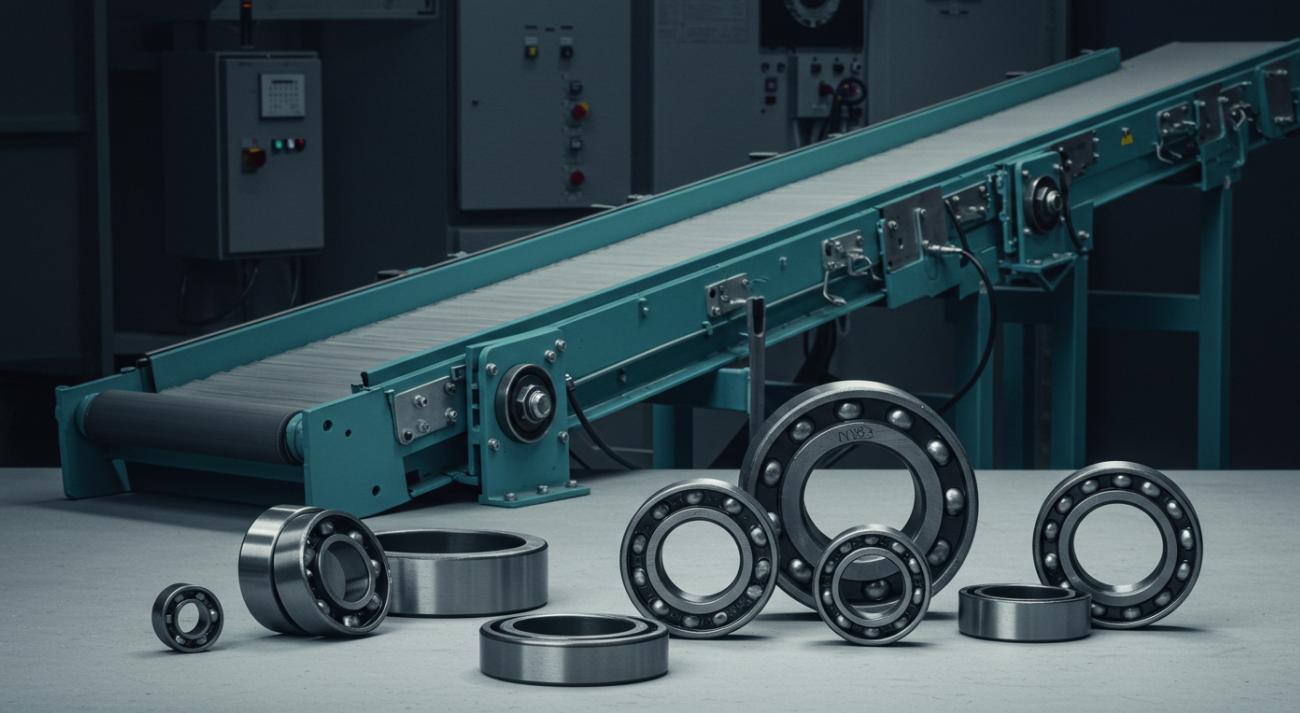

As global attention shifts toward sustainability, industries are rethinking their processes. One overlooked yet crucial component in this movement is the industrial bearing. These small parts play a major role in keeping machinery running, but they also carry environmental consequences. Choosing eco-responsible bearings is now a smart step for businesses seeking performance and sustainability in equal measure.

Why Eco-Responsible Bearings Matter in Industry?

Industrial bearings affect more than just machinery. Their materials, production methods, and disposal all contribute to a product’s environmental footprint. When businesses choose sustainable alternatives, they help reduce emissions, minimize waste, and support circular manufacturing practices.

Environmental Impact of Traditional Bearings

Conventional bearings are often made from mined steel or other heavy metals, requiring large amounts of energy and water. Their production emits greenhouse gases and generates industrial waste. Additionally, most rely on petroleum-based lubricants, which, when leaked or improperly disposed of, pollute surrounding ecosystems.

Understanding Eco-Friendly Bearing Options

Eco-responsible bearings are designed with environmental performance in mind. They may be made from bio-based polymers, ceramics, or recycled metals. These materials reduce energy use during production and are easier to recycle or dispose of responsibly. More importantly, many of these bearings are built to last longer, reducing the need for frequent replacements and conserving resources over time.

What to Consider When Choosing Sustainable Bearings

Making an eco-responsible choice isn’t just about the label, it’s about understanding every aspect of a bearing’s life cycle. Here are the most important factors to evaluate.

Materials That Minimize Impact

Materials are the starting point for sustainability. Bio-based polymers break down naturally and reduce dependence on oil. Recycled metals help avoid the environmental toll of mining. Ceramic options offer long lifespans and lower maintenance, cutting resource use over time. Each option carries distinct benefits depending on the industry’s needs.

Energy-Efficient Bearing Design

Design matters. Bearings that use advanced engineering to lower friction and distribute load evenly help machines work more efficiently. They reduce wear, extend equipment life, and cut down on overall energy use. These improvements also mean fewer replacements, which translates to less waste and lower operating costs.

The Role of Lifecycle Thinking

A bearing’s sustainability should be evaluated across its entire lifecycle—from raw material extraction to end-of-life disposal. Products that can be recycled, reconditioned, or reused extend their utility and reduce landfill waste. Businesses that understand and manage this lifecycle contribute significantly to environmental goals.

The Only Checklist You Need

When deciding on sustainable bearings, focus on these essential points:

- What materials are used, and are they recycled, recyclable, or biodegradable?

- Does the bearing reduce friction or energy use in machines?

- Is the product built to last longer and require fewer replacements?

- Can it be maintained easily with eco-friendly lubricants?

- Is the manufacturer committed to sustainable practices and certified for them?

This checklist can guide you toward better choices without sacrificing performance.

Working with the Right Supplier

Not all bearing suppliers prioritize sustainability. Choosing the right partner ensures access to eco-certified products, ethical sourcing, and reliable guidance. A good supplier will be transparent about their materials and processes and will help you meet both regulatory and environmental targets.

Evaluating Long-Term Value Over Cost

While eco-responsible bearings may seem more expensive upfront, they often deliver better returns. Their extended lifespan and efficiency reduce maintenance needs. Companies also benefit from improved brand image, stronger compliance with green standards, and increased trust from customers who value sustainability.

Quick Comparison of Eco-Friendly Bearing Types

| Bearing Type | Environmental Impact | Key Advantages |

|---|---|---|

| Ceramic Bearings | Low production energy, long-lasting | Durable, minimal maintenance |

| Recycled Metal Bearings | Reduced mining and material waste | Cost-effective, easy to source |

| Bio-based Polymer Bearings | Biodegradable and petroleum-free | Lightweight, ideal for specific applications |

Maintenance and Disposal for a Greener Lifecycle

Eco-friendly bearings are most effective when paired with responsible maintenance. Using plant-based or biodegradable lubricants, inspecting parts regularly, and disposing of used bearings through recycling or manufacturer take-back programs help maximize their benefits. These small efforts reduce waste and increase operational sustainability.

In sum, eco-responsible industrial bearings aren’t just good for the planet, they’re smart for business. With better materials, energy-efficient designs, and a longer lifecycle, they bring value beyond cost savings.

Looking to upgrade your systems with sustainable bearing solutions? Trust Ontario Belting, a leading supplier in eco-friendly industrial components. Their experienced team can help you choose the right products for your operations while meeting today’s environmental standards. Contact them today to start building a cleaner, more efficient future.

https://www.youtube.com/watch?v=qfusFZMh6UY